With the Evershield® Anodising 50-Year Warranty, AAF offers peace of mind that architectural aluminium will remain vibrant, resilient, and beautiful for generations.

August 20th, 2025

With a growing number of architects and builders making sustainability and lifecycle thinking core to specification and procurement decisions, AAF (Australian Aluminium Finishing) are providing a credible and beautiful solution for architectural features.

For a sustainable future, finishes are an important visual element. We can now choose finishes with a 50-year warranty that endure the full serviceable life of our built environment. Fundamental tenets for the sustainability of materials include minimal use fossil fuels in the manufacturing process, and robustness and extended lifespans, whereby a product can be reused, recycled or repurposed at end of life.

Positive environmental attributes

Aluminium offers multiple benefits for architecture and construction, including being 100% recyclable. The finish on the material, however, can make a marked difference in its durability, aesthetic longevity and environmental impact. Traditional powder coatings or wet paint coating which contains polymers , and as organic coatings would limit the lifespan of the coating in the harsh Australian climate .

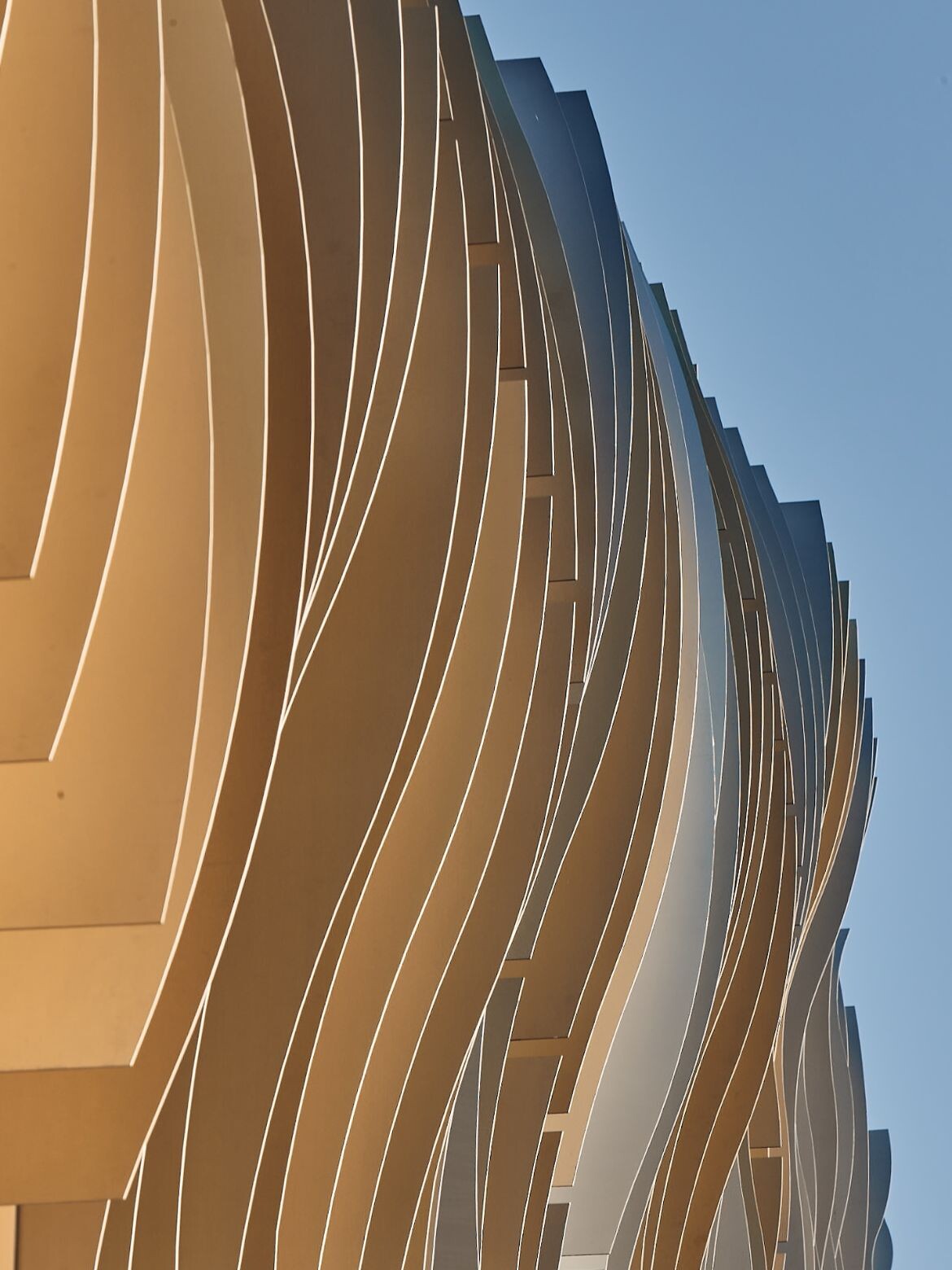

By contrast, anodising is an electrochemical process can also be powered by renewable energy. The anodising process delivers colours and luminosity which are inherently part of the material, offering designers and specifiers a wide array of options for creating lasting beauty.

The finish cannot flake, peel or blister, and has extreme UV-resistance, so it will not fade and discolour as the summers pass. This makes anodised aluminium features ideal for facades that will be exposed to the Australian climate, and even in extreme weather conditions, while also reducing the need for maintenance or complete replacements where the colours of th ecoated aluminium is also integral in the architectural design..

An industry-leading warranty

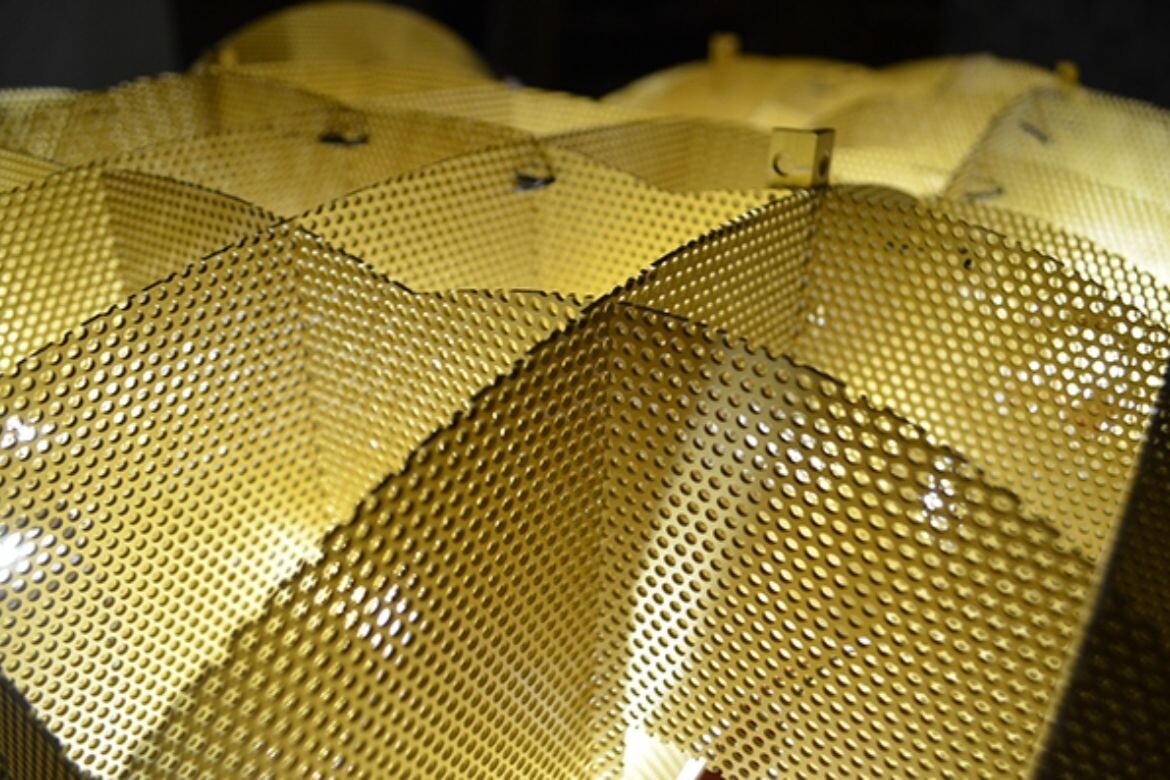

AAF’s Evershield anodised finishes for aluminium-based materials and products including façade panels, shade structures, balustrades and sculptural elements also now come with a science-backed 50-year warranty. This extended lifespan contributes further to a reduced embodied carbon footprint over the lifespan of the product or project – and because there are no organicl surface coatings or powder coatings involved, the aluminium remains 100% safely recyclable.

The proprietary Evershield® anodising process forms an extremely hard, integral oxide layer on the aluminium surface which is essentially corundum (aluminium oxide) — the same material as sapphire making it significantly more resistant to scratching, chipping, and UV degradation.

The outstanding results can be seen on some of Australia’s largest building and infrastructure projects, including Perth Stadium, , Westconnex in Sydney, Sydney Cricket Ground, Chadstone Shopping Centre and Melbourne University’s School of Design.

Robust and credible verification

AAF also recognises the importance of credible, third-party verification of product claims. The quality of Evershield anodised finishes exceeds the AAMA 611 and AS1231 performance standards. It has been independently assessed by engineers as achieving durability up to 40% beyond the minimum threshold set by the standards.

In Canadian and USA Environmental Product Declarations (EPDs) data shows that anodising has a 40% lower carbon footprint than powder coatings. This is partly due to the fact powder coatings involve multiple petrochemicals which each have a significant energy and embodied carbon footprint from their manufacturing. Anodising, by contrast, only accrues carbon impacts from the energy used by the electro-chemical process.

Independent environmental scientists KMH Environmental have also undertaken Lifecycle Assessment (LCA) of the products, verifying the anodising performance and impacts across a 50-year lifetime.

In addition, audits of exemplar projects such as Oxford’s Bodleian Library (completed in 1940) and Milan’s Montecatini (completed in 1938) demonstrate the capabilities of anodising to resist corrosion and maintain the integrity of features, finishes and fixtures.

AAF has also undertaken ongoing audits of completed projects to verify the performance and quality of their products in-situ. AAF facilities in Sydney, Brisbane and Melbourne are also regularly independently audited to ensure they comply with the company’s rigorous anodising quality management policies.

In a market where even whole buildings may only carry a 20-year warranty finish warranty, the launch of Evershield’s 50-year warranty is tangible evidence of AAF’s commitment to exemplary workmanship and responsible manufacturing processes. It also demonstrates a dedication to ensuring project designers and specifiers can confidently take full advantage of the aesthetic and creative potential of anodised aluminium products.

INDESIGN is on instagram

Follow @indesignlive

A searchable and comprehensive guide for specifying leading products and their suppliers

Keep up to date with the latest and greatest from our industry BFF's!

The new range features slabs with warm, earthy palettes that lend a sense of organic luxury to every space.

A curated exhibition in Frederiksstaden captures the spirit of Australian design

Gaggenau’s understated appliance fuses a carefully calibrated aesthetic of deliberate subtraction with an intuitive dynamism of culinary fluidity, unveiling a delightfully unrestricted spectrum of high-performing creativity.

Reuse, resourcefulness and material transformations bring unexpected stories to Arup’s new Brisbane office, designed by Hassell.

With prime views over Japan’s Mount Fuji, Yū Momoeda’s sauna facility defies typical standards to respond to the undulations of nature.

THISS Studio has completed the interior fit out of a flexible office and creative space in east London for independent communications studio, SALT.

The internet never sleeps! Here's the stuff you might have missed

Winner of the INDE.Awards 2025 Best of the Best, Terminal 2 Kempegowda International Airport Interiors by Enter Projects Asia and SOM showcases 12,000-square-metres of biophilic design, featuring nine kilometres of handwoven rattan in a sustainable, world-class passenger experience.

Architectus Principals Simone Oliver and Patricia Bondin are set to speak at WORKTECH Sydney this year, so we asked them for some sneaky early insights on workplace design.