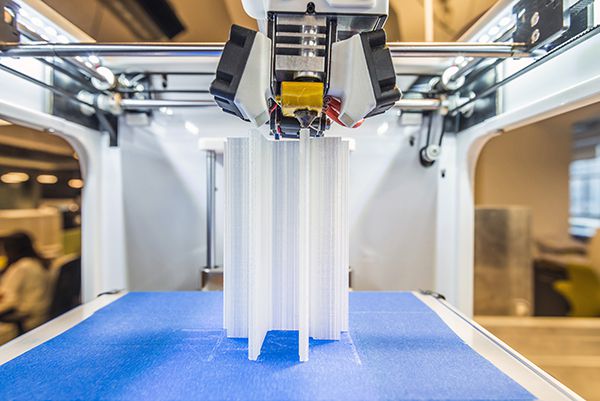

How JEB International is using 3D printing to enhance its design process.

April 7th, 2016

A key part of the new JEB International headquarters in Hong Kong is the design workshop – the centrepiece of the new office. The space is visible through glazed partitions, meaning visitors and staff can look on as mockups are created in real time. Within the workshop are drill presses, bench saws and testing apparatuses. Perhaps most exciting are two state-of-the-art printers. Up until the installation of these printers, 3D printing had not been a part of the JEB design process.

The new printers have enhanced JEB’s design process – adding speed, and building upon form and function and customization in the development of JEB’s acoustic glazed partitions and doors.

Speed

The design of aluminum and glass partitions normally starts with aluminum profiles. In the past, the JEB industrial design team would come up with new concepts, review and improve them through drawings, and then decide whether to green light the cutting of a new die and the extrusion of a sample. This design and testing process would take up to 10 weeks for a single extrusion. Through 3D printing, not only has the cost of producing die cuts and extrusions been eliminated, but the speed to print out a concept can now be done in nearly real time. In the best cases, we can have a 3D printed sample on our desks and ready for review within 24 – 48 hours.

Form and Function

Using 3D printers, JEB can actually build models made up of multiple extrusions to see how different components of the system can work together. For example, the JEB team can test how brackets and stakes work with flutes, how door leaf profiles interact with door frames and how various gaskets and seals work with alternating thicknesses of glass. This has allowed JEB to push the design process even further – rather than shelving an idea that we weren’t too sure about investing bin, we can physically see what is limiting the design, and from there decide how to improve it before moving on.

Customisation

JEB has continually offered its clients the ability to customise products to their specifications – it is quite rare that a major project built by JEB, anywhere in the world, doesn’t involve some level of customisation. 3D printing means that JEB is able to review and improve designs first hand, while architects and designers working with JEB can physically inspect prototypes just days after the initial brief.

New Products

True testament to the success of JEB’s 3D printers has been the release of two new products, launched in recent months. Summit is a thin, double-glazed partition system, developed for simple and efficient installations. Brooklyn is an innovation, and contemporary version of steel framed windows.

INDESIGN is on instagram

Follow @indesignlive

A searchable and comprehensive guide for specifying leading products and their suppliers

Keep up to date with the latest and greatest from our industry BFF's!

A longstanding partnership turns a historic city into a hub for emerging talent

Hassell has revealed the design for a groundbreaking community building in Tanzania, a project in collaboration with the Australian-based charity, One Heart Foundation.

Singaporean studio Produce was recognised with the Best of the Best accolade at the INDE.Awards 2019, partnered with Zenith. We unpack the innovative and progressive spirit that earned them this ultimate regional honour.

The internet never sleeps! Here's the stuff you might have missed

Collingwood is one of three precincts at Saturday Indesign 2025 on 6th September – find out what’s on there!

Designed by DKO, the latest Ingenia Lifestyle Element resident clubhouses at Fullerton Cove and Natura at Port Stephens focus on the lifestyle needs of a changing over-55s demographic.