A D Lab humanises ‘buildability’. Monomer House 1, developed using a system from light-gauge steel-manufacturer Lightrus, is currently on display at the National Design Centre’s rear court.

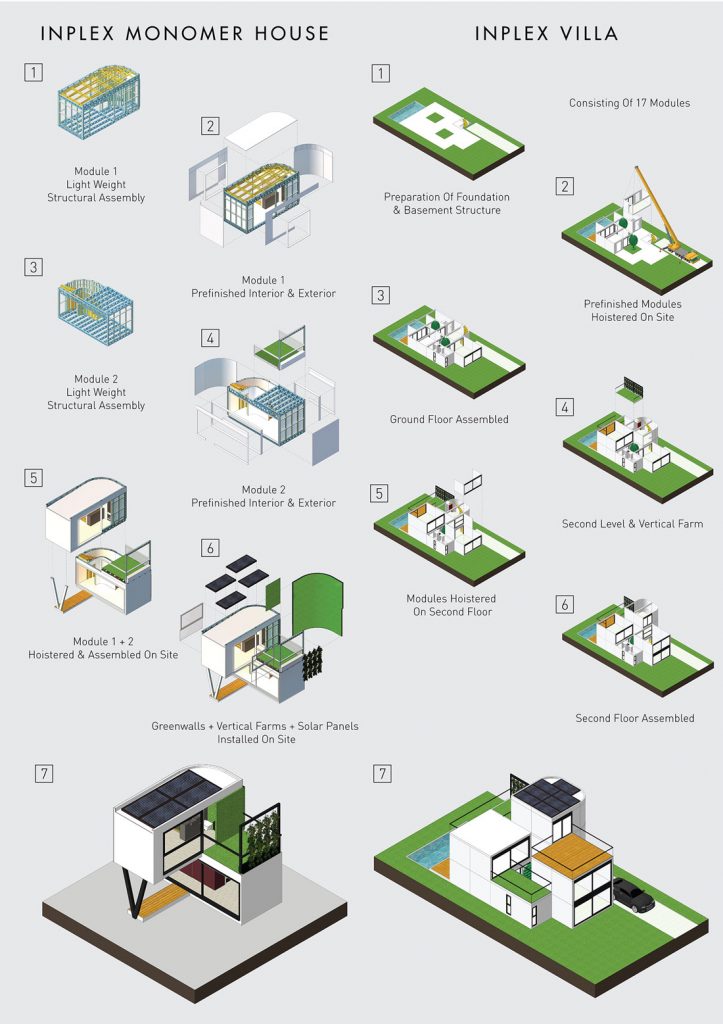

Diagrams for a house (left) and villa (right)

August 6th, 2018

Light-gauge steel frame systems have been identified by Singapore’s Building and Construction Authority (BCA) as one of the construction methods that can improve buildability and productivity for small landed residential developments, yet they are still rarely used for such projects here.

“We’ve been interested in this technology for a while now,” says Darlene Smyth, Manager of architecture studio A D Lab. “We’re actually doing two houses here in Singapore using this technology at the moment. One of them would have required piling otherwise, so aside from saving money, we’ve saved time and labour. It’s much less labour-intensive than typical concrete and brick construction systems.”

Now, working with a steel framework from BCA-approved* steel PPVC (pre-fabricated prefinished volumetric construction) system supplier Lightrus, A D Lab has developed a prototype house. It’s currently on display downstairs from the A D Lab studio at the rear court of the National Design Centre, where it was installed for the recent Playground of Infinite Happiness event. It should remain there for at least the next few months.

“We haven’t designed this steel system,” explains Smyth, “but we’ve designed it into a product. Systems like this are more often used for industrial buildings, but actually they make a lot of sense for homes in the tropics because concrete and brick absorb heat and dissipate it at night. The prototype is more efficient in terms of heat gain, it’s light and faster to build, and it’s a lot quieter to construct. It just makes sense to use this technology.”

Smyth and the team at A D Lab recognised the opportunity offered by light-gauge steel systems in the context of the industry’s move toward less labour-intensive, cleaner and greener products. “But we saw that these systems weren’t designed in a way that was adaptable to different situations. That’s where we came in, and we brought in a lot of collaborators who use green technologies,” she explains.

Monomer House 1 consists of two modules (downstairs and upstairs), stacked at a 90-degree angle to create an overhang and a sheltered outdoor space. The modules were craned into place from the neighbouring cathedral grounds and fixed into place without welding. Downstairs are a living room, kitchen (with built in appliances), deck and green wall; upstairs are the bedroom (designed to incorporate a fold-out bed), bathroom and balcony with a vertical garden. Each module is around the size of a car-parking bay, so space-efficient planning was carefully applied. Assembly of the prototype took around five days.

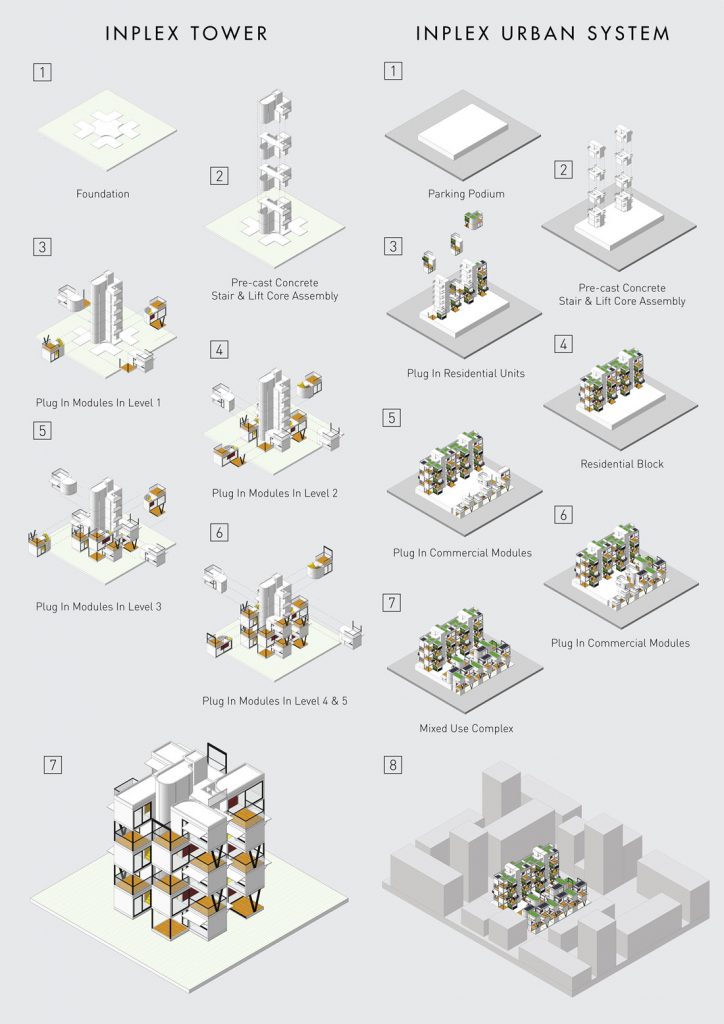

Smyth explains that the framework could be applied to many situations. “It’s very adaptable for buildings that contain repetitive units – student housing, malls, office complexes, factories,” she says. Displayed with Monomer House 1 are diagrams of how the framework could be applied in a larger villa format, as a tower, or as an urban system. She adds, “We’ve designed systems so you can plug it in – like a Lego piece – and create a self-supporting building up to five storeys. Taller than that, you need a core to plug the modules into.”

It’s a system for portable architecture. Says Smyth, “You could install this on one site, pack it up and move it to another site. You could even move it overseas. It’s shippable,” she explains, noting that two modules can fit on a flatbed truck.

The prototype at NDC was assembled with contributions from Lightrus, CMP, Ace Builder, Bluescope, LME Singapore, Greenology, Ramboll, M Metal, USG Boral, Light Basic Studio, ProFloorz, Matcha Builder, Hafary, Grohe, Nippon Paint, American Standard, EDL, EnerGreen Technologies, Fisher & Paykel, Epfoluos and PvFoundry.

*Lightrus has achieved ‘in principal’ approval from the BCA as a steel PPVC system supplier, pending formal addition to the authority’s ‘Manufacturer Accreditation Scheme’ list.

Diagrams by A D Lab. Photos of Monomer House 1 by Narelle Yabuka.

INDESIGN is on instagram

Follow @indesignlive

A searchable and comprehensive guide for specifying leading products and their suppliers

Keep up to date with the latest and greatest from our industry BFF's!

Herman Miller’s reintroduction of the Eames Moulded Plastic Dining Chair balances environmental responsibility with an enduring commitment to continuous material innovation.

In a tightly held heritage pocket of Woollahra, a reworked Neo-Georgian house reveals the power of restraint. Designed by Tobias Partners, this compact home demonstrates how a reduced material palette, thoughtful appliance selection and enduring craftsmanship can create a space designed for generations to come.

True luxury strikes a balance between glamorous aesthetics and tactile pleasure, creating spaces rich in sensory delights to enhance the experience of daily life.

At the Munarra Centre for Regional Excellence on Yorta Yorta Country in Victoria, ARM Architecture and Milliken use PrintWorks™ technology to translate First Nations narratives into a layered, community-led floorscape.

Steelcase has unveiled one of its largest Asia Pacific showrooms in Hangzhou, merging workplace, brand experience and client engagement in a single flexible environment designed by M Moser.

Melbourne-based Studio Edwards has designed Shift+Space, a modular system under the banner of ‘adaptive retail architecture’. Ben Edwards tells us more.

The internet never sleeps! Here's the stuff you might have missed

As 2026 gathers pace, Davenport Campbell Principal Neill Johanson argues that the people-place-process nexus in workplace design just won’t cut it any longer.

Hammond Studio has completed its own workplace in Sydney, placing great emphasis on collaborative technology, light and of course high-quality detailing.